Wiwa

You can always depend on Wiwa for coating protection after any work with 100% certainty.

Herkules GX

Oil free and low icing, technically optimized high performance air motor

material pump and HP filter made from stainless steel

Coarse threads for easy assembly and disassembly of the material pump

Deep-tread tires also suitable for difficult terrains

WIWA PROFESSIONAL CLASSIC

For industrial coating work of any kind

Optimal for longer material hoses, larger nozzle bores and high spray pressures

Due to the high pressure ratio, particularly suitable for processing highly viscous low solvent and solvent-free materials with a high solids content

The WIWA series for heavy-duty corrosion protection.

WIWA HERKULES GX PFP

Passive fire protection is primarily used to maintain the functionality of structures, pipelines and containers for a defined period of time, since at temperatures of approx. 550°C the critical core temperature is reached and structures are at risk of collapse. In the event of a fire, the flame retardant material foams up, thus limiting the temperature development in the respective critical range over time. This saves important time for rescue and evacuation measures.

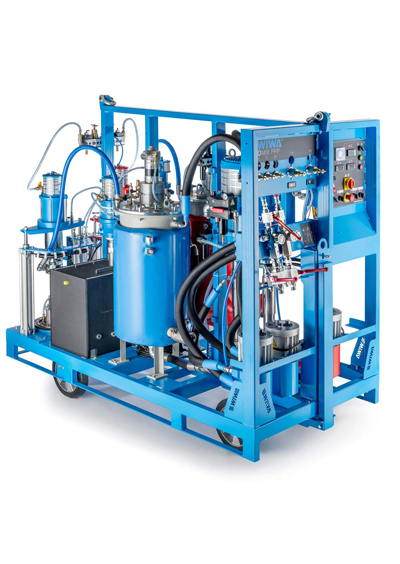

WIWA DUOMIX 333 GX PFP

In close cooperation with leading paint manufacturers, WIWA has further developed and optimized its high-performance 2K and 3K application systems. The latest development stage is the smooth processing of an already proven intumescent material. Following successful tests, International Coatings Ltd. has issued equipment certification for the WIWA 2K unit 333 GX PFP.

WIWA DUOMIX PU HX

This hydraulic, compact, mobile and versatile unit processes almost all polyurethane foams and fast reacting polyurea.

The WIWA DUOMIX PU HX unit is equipped with an energy-saving mode as standard. This detects the system status during coating and automatically switches off consumers that are not currently required.

WIWA INJECT HD 2

The injection units HD 2 are particularly suitable for the injection and pressure grouting of low viscosity epoxy or polyurethane resins and meet the requirements of the Supplementary Technical Conditions for Cracks.

WIWA INJECT 2K 230

Due to the positive control and always the same switching points, you get the perfect dosing with the WIWA INJECT 2K 230. It is strongly characterized by its high delivery rate. In addition to the standard mixing ratio of 1:1, over 100 other mixing ratios are possible by replacing the material pumps. Aqueous and low-viscosity as well as high-viscosity materials are no problem

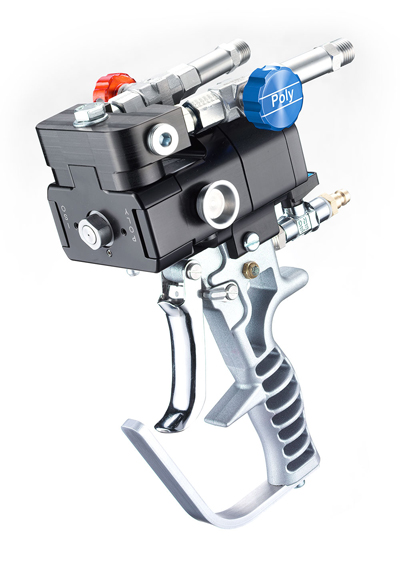

WIWA PU GUN 4040 manual gun

The pneumatically operated 2K gun can be quickly and easily adapted to all customer requirements and stands for optimum working ergonomics thanks to its low weight, optimized handle design and variable arrangement of the connections for the material feed hoses. This means that even large areas can be coated without fatigue. The simple exchange of the adapter for the automatic gun for a handle also makes the PU GUN 4040 ready for flexible use in manual operation.

WIWA 500 F

All parts in contact with the material are made of stainless steel and therefore the 500 F is also ideally suited for waterborne paints. For constant material temperatures, we recommend the WIWA hot spray circulation system with return manifold.

WIWA 500 D

The WIWA 500 D is a handy airless spray gun. The ball-bearing mounted swivel joint ensures optimum maneuverability.

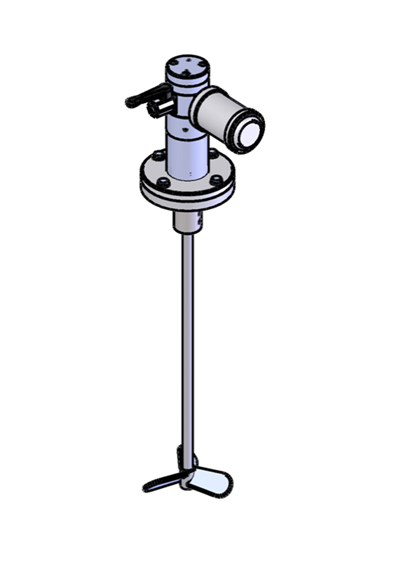

WIWA pneumatic tank agitators

Customer benefit and reliability of the agitators always come first, regardless of size and complexity. From the wide portfolio of highly efficient WIWA agitators, the optimum system for almost any task can always be found. All parts in contact with the material are made of stainless steel.

Pipe Coating

Pipes with a diameter of 50 - 800 mm are coated from the inside with a spinning wheel without rotating the pipe. Coating takes place in the backward movement of the traversing unit used. For pipes with a diameter of 50 - 100 mm, a spinning wheel with two centering devices suitable for the corresponding pipe diameter is required. For pipes with a diameter of 100 - 400 mm (optionally up to 800 mm) we offer continuously adjustable centering devices.

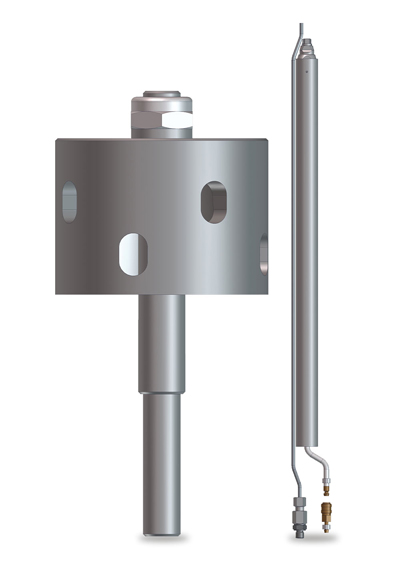

WIWA material fluid heater

No runners on vertical surfaces, savings on solvents and energy, and excellent surface quality - with the explosion-proof WIWA material fluid heaters, highly viscous materials can be processed easily and efficiently. The explosion-proof units are available for high and low pressure and have a T4 temperature classification. The heat exchanger can be flexibly positioned and easily replaced. We also offer an optional RFA version for external control.